Palm kernel shells, a byproduct of palm oil production, have gained significant attention as a renewable resource for charcoal production. These shells are not only abundant but also offer unique properties that make them highly suitable for conversion into charcoal. Utilizing a palm kernel shell charcoal machine allows for the efficient transformation of this agricultural residue into a valuable product with wide-ranging applications.

The Composition of Palm Kernel Shell

Palm kernel shells are dense, fibrous materials derived from the crushing of palm fruit kernels. Their unique composition makes them ideal feedstock for charcoal production:

- High Carbon Content: The shells are rich in carbon, a key factor in producing high-quality charcoal with excellent energy output.

- Low Moisture Content: Palm kernel shells typically have low inherent moisture, reducing the need for extensive drying before processing.

- High Volatility: This characteristic enhances the combustion properties of the resulting charcoal, making it an effective energy source.

- Uniform Size and Density: Their consistent size and density ensure efficient processing in a palm kernel shell charcoal production machine, minimizing energy consumption and maximizing yield.

Environmental Advantages

1. Waste Valorization

Palm kernel shells are often discarded as agricultural waste, leading to disposal challenges and environmental pollution. Converting these shells into charcoal through pyrolysis provides an environmentally friendly solution by:

- Reducing waste accumulation.

- Diverting organic material from landfills.

- Mitigating the release of methane, a potent greenhouse gas, from decomposing shells.

This process aligns with circular economy principles, turning waste into a sustainable resource.

2. Carbon Neutrality

Palm kernel shells are a renewable resource, and their use in charcoal production is considered carbon-neutral. The carbon dioxide released during the combustion of charcoal made from palm kernel shells is offset by the carbon absorbed by the palm plants during their growth. This contrasts with fossil fuels, which contribute to net increases in atmospheric carbon dioxide.

Economic Benefits

1. Abundant and Low-Cost Feedstock

Palm kernel shells are a byproduct of the palm oil industry, which is prevalent in regions such as Southeast Asia, Africa, and South America. Their abundance ensures a steady and low-cost supply of raw material for biomass carbonization machine, making it an economically viable option for industries and small-scale operators alike.

2. High Market Demand

Charcoal derived from palm kernel shells has diverse applications, including:

- Energy Production: Used as an industrial fuel in cement, steel, and power generation sectors.

- Activated Carbon: Palm kernel shell charcoal is processed into activated carbon for water purification and air filtration applications.

- Household Use: High-quality charcoal is a preferred fuel for cooking and heating, especially in regions where conventional energy sources are limited or expensive.

Technological Advancements in Charcoal Production

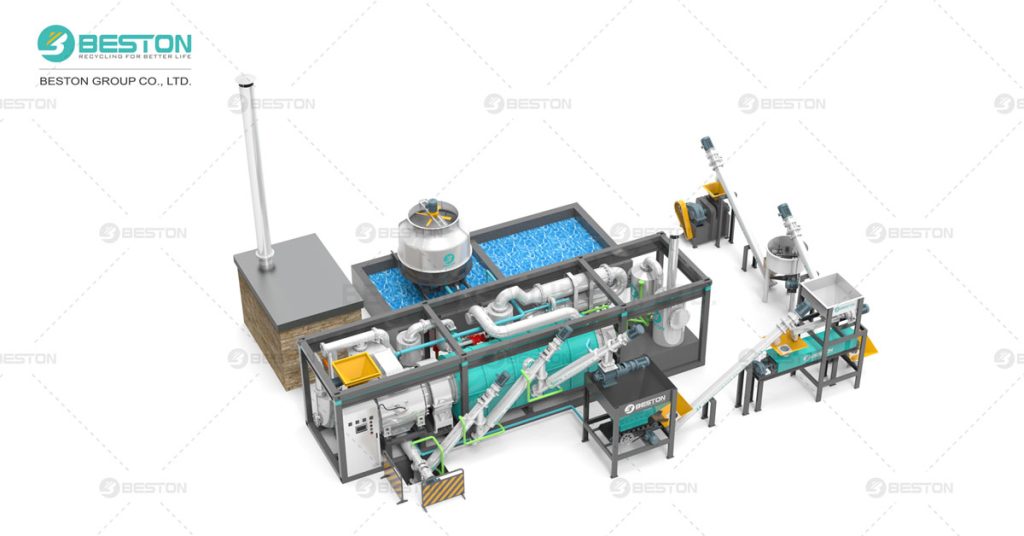

The advent of modern palm kernel shell charcoal machines has revolutionized the production process. These machines are designed to operate efficiently and sustainably, incorporating advanced features such as:

- Continuous Operation: Ensures consistent production rates and minimizes downtime.

- Energy Recovery Systems: Captures and utilizes heat generated during pyrolysis, improving energy efficiency.

- Emission Control: Equipped with gas scrubbers and filters to minimize environmental pollution.

Such advancements not only enhance the economic viability of charcoal production but also ensure compliance with environmental standards. If you would like to obtain a solution for producing clean palm kernel shell charcoal, please consult Beston China.

Superior Properties of Palm Kernel Shell Charcoal

Charcoal made from palm kernel shells exhibits superior properties compared to other biomass-based charcoals:

- High Energy Density: The charcoal’s high fixed carbon content ensures longer burn times and greater energy output.

- Low Ash Content: This results in cleaner combustion, reducing maintenance requirements for equipment and stoves.

- Durability: Palm kernel shell charcoal is dense and less prone to crumbling, making it easier to transport and store.

These attributes make it a preferred choice for both industrial and domestic applications.